Rib & Infill Flooring

Description

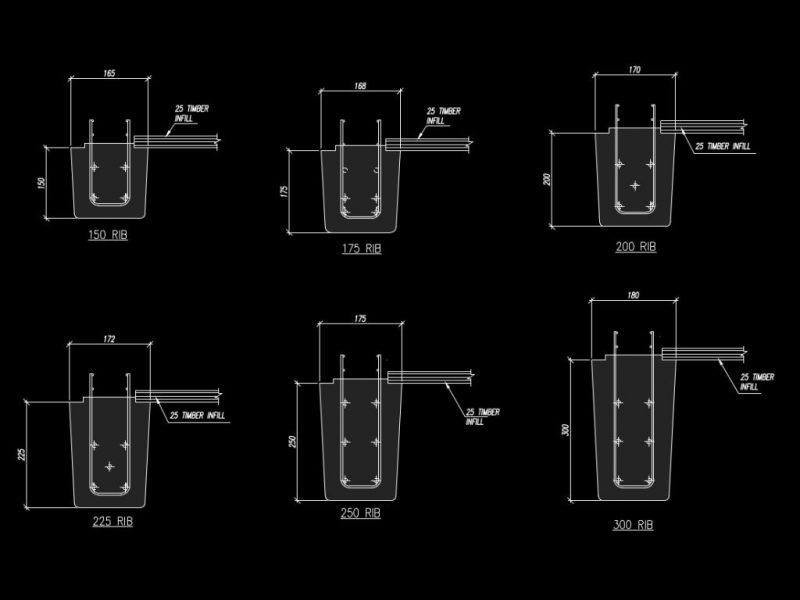

The Rib & Infill flooring system consists of 200mm wide precast prestressed concrete ribs spaced generally at 900mm centres with timber infills placed between them. The ribs have variable depths to suit the projects load/span requirements.

This multi-piece system is tied together with a 75mm in-situ concrete topping and mesh reinforcing.

The system has the benefit of being suitable for those tricky sites where access is a problem or poor foundation conditions dictate the use of a comparatively lightweight floor.

Timber Infills

Timber infill planks are typically merchant grade rough sawn timber. The infill plank depth is typically 25mm although this does vary depending on availability. Timber infills should be dampened prior to placing the concrete topping. Alternative timber types can be left with an exposed underside finish to create an architectural feature, e.g. polyurethaned macrocarpa or rimu.

Sound Transmission

One of the major features of a concrete floor is the low sound transmission.

Transport & Erection

Ribs must be handles and stacked at two points, at, or directly beside the lifting eyes. It is recommended that ribs be seated 75mm onto the supporting walls/beams.

Fire Resistance Rating

Standard rib & infill provides a 1 hour fire resistance rating. Increased fire ratings can be achieved with specific design.

Materials

Rib Strength = 45 MPa at 28 days

Topping Strength = 25 MPa at 28 days

For further advice on flooring systems or technical information please contact Ultimate Engineered Concrete, our experienced and qualified staff will be happy to discuss your flooring design.